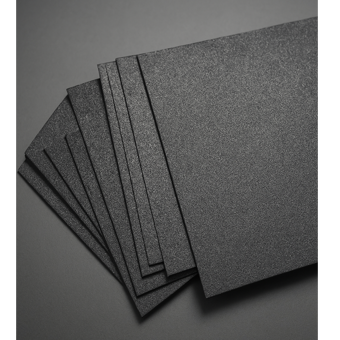

In MICROSINF-SS, diffusion-bonding process is the key. Porous stainless steel materials are layered, woven or pleated to provide the proper combination of application properties, as fine filtration, flow resistance, pressure drop, cooling efficiency and more. The entire unit is then sintered at high temperature in a controlled atmosphere furnace to diffusion bond all the layers and every contact point. This creates a sintered laminate bonded media that is surprisingly strong, ductile and corrosion resistant. They are durable and non-absorbent, they can be backwashed, cleaned and reused.

MATERIAL OF CONSTRUCTION

| Filter Medium* | Stainless Steel 316L |

| Support layer* | SS316 |

| Core/Cage/End Caps* | SS316 |

| O ring/Gasket | Silicon/EPR/PTFE/Viton |

CARTRIDGE DIMENSIONS (NOMINAL)

| Outer Diameter | 63.0 mm (2.48”)|75 mm (2.95”)* |

| Length | 10”, 20”, 30”, 40” |

| Effective filtration area (10" cartridge)* | 0.15 m2 |

MICRON RATINGg(µ)*

| Micron Rating(µ) | 10, 20, 40, 100* |

OPERATING CONDITION

| Temperature(Max) | 150 0C/3020F |

| Pressure (Max) | 7 Bar /101.5 psi |

| pH value | 1-14 |

- Diffusion bonded

- SS Sintered Fiber

- Reusable

- Cleanable

- Low Flow resistance

- Suitable for the extreme operating environments

- Pharmaceuticals: Prefiltration & decarbonate filtration

- Recovery of catalyst

- Food & Beverages: Filtration of viscous liquid with high temperature.

- Fine Chemicals: Strong acid & alkaline filtration.

- Water: Filtrate the O-zone containing water.

- Steam filtration.